Introduction

The Thai Agricultural Standard (TAS) 9046-2017, Good Manufacturing Practices for Frozen Durian, has been developed to establish guidelines for all stages of durian processing into frozen products — from raw material receiving, inspection and selection, sanitation of premises, equipment, and personnel, to chilling and transportation — in order to ensure that frozen durian is safe, hygienic, and of high quality in accordance with international standards.

Objective

It is intended to control and upgrade the production process of frozen durian in compliance with good hygienic practices, in order to ensure safe and high-quality export, build confidence among importing countries, and promote the long-term sustainability of Thailand’s trade and economy.

Whole fruit

flesh with seed

flesh without seed

Key requirements for the production of frozen durian

Summary of TAS 9046-2017: Good Manufacturing Practices for Frozen Durian

Key points for the production of frozen durian

The Agricultural Standards Act B.E. 2551 (2008), the Thai Agricultural Standard (TAS) 9046-2017 on Good Manufacturing Practices for Frozen Durian has been designated as a mandatory standard, applicable to frozen durian intended for export. The objective is to upgrade the quality and safety of the product in response to the increasing volume of export, while recognizing that some producers still lack proper hygienic practices. Therefore, the Ministry of Agriculture and Cooperatives considers it appropriate to urgently establish this standard for the economic benefit of the country.

Advantages of the enforcement of the standard

- To build confidence in Thai frozen products as safe and of high quality.

- To strengthen and enhance the competitiveness of Thailand’s frozen durian export business.

- To enhance the production of high-quality agricultural products.

Who shall comply with the mandatory standard

- Producers of frozen durian intended for export

- Exporters of frozen durian

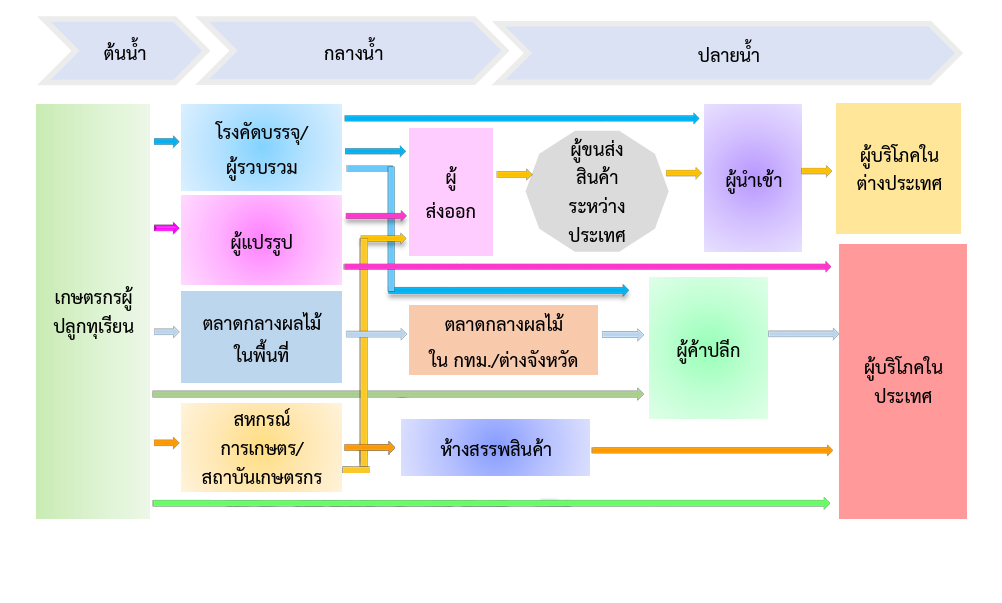

Three main parts of the supply chain for durian production for export

Upstream – Durian growers manage production starting from the preparation of inputs, registration under GAP, and the management of product quality to be ready for sale.

Midstream – Collectors (collecting houses), packing houses, processing plants, central markets, and cooperatives shall be responsible for sorting, quality inspection, application of post-harvest technology, packaging, transportation, and distribution of products to the market or exporters.

Downstream – Wholesalers, retailers, and exporters shall be responsible for distributing products to consumers in both fresh and processed forms, as well as for customer acquisition and building consumer satisfaction.

Academic Papers

Project on the Study of the Relationship between the Weight of Fresh Durian and Frozen Durian

This academic document focuses on Frozen Durian, serving as a guideline for production and quality control for export purposes. It aims to ensure that the production process complies with food safety standards while preserving the sensory qualities of durian to remain as close to the fresh fruit as possible. The content covers key processes including the selection of durians at the proper ripening stage, peeling and separating the flesh in a clean environment with temperature not exceeding 15 °C, freezing at temperatures below −35 °C to prevent large ice crystal formation, packaging in tightly sealed food-grade materials, and maintaining storage and transportation at temperatures not higher than −18 °C. These procedures are designed to comply with TAS 9046-2564 (Frozen Durian Standard) and international food safety systems such as GMP, HACCP, and ISO 22000, which help enhance the quality of Thai durian and strengthen consumer and market confidence—particularly in China.