Introduction

The Thai Agricultural Standard, TAS 1004-2014, “Code of Practice for Sulphur Dioxide Fumigation of Fresh Fruits,” was established to control the fumigation of fresh fruits with sulphur dioxide, aiming to reduce chemical residues in fruits while maintaining their quality, appearance, and safety prior to distribution to domestic consumers and for export. At present, sulphur dioxide fumigation is applied to extend the shelf life of fresh fruits and preserve their freshness; however, excessive residues may affect consumer health. Therefore, the fumigation process must be controlled so that residue levels do not exceed those prescribed by law, in order to ensure consumer safety and enhance confidence in Thai fruits both domestically and in global markets.

Objective

This agricultural standard establishes the code of practice for the fumigation of fresh fruits with sulphur dioxide gas in order to obtain fresh fruits that are safe, of quality suitable for consumption, and without adverse impact on the environment.

Scope

This agricultural standard establishes the code of practice for the fumigation of fresh fruits with sulphur dioxide gas in order to obtain fresh fruits that are safe, of quality suitable for consumption, and without adverse impact on the environment.

Key requirements for the production of frozen durian

Summary of TAS 1004-2014 “Code of Practice for Sulphur Dioxide Fumigation of Fresh Fruits

The four mandatory requirements to ensure compliance with the standard

1. Establishment

- Location It shall not cause any contamination to fresh fruits or any adverse impact on the environment, and if there is any risk, preventive measures shall be in place and authorization shall be obtained in accordance with the law.

- Sufficient space For operations covering raw material receiving, fumigation, and post-fumigation handling.

- Fumigation chamber The chamber shall have a sturdy structure with smooth surfaces free from cracks, constructed with materials resistant to leakage and gas absorption, easy to clean, equipped with an observatory window, adequate lighting, and an air circulation system that disperses the gas throughout the chamber.

- Tools and equipment Tools and equipment shall be in good condition, effective, accurate and precise, suitable for their intended use, and shall include a reliable weighing scale and timer.

- Occupational safety for workers Tools and equipment shall be in good working condition and in sufficient quantity for workers, and safety signs shall be provided at the workplace.

2. Operation Control

- Raw materials Fresh fruits shall be inspected upon receiving in accordance with the establishment specifications to ensure their suitability for use.

- Containers for fresh fruits Containers shall be clean, strong, and suitable for packaging so as to allow the gas to pass through and ensure that fresh fruits are fully exposed during fumigation.

- Sulphur dioxide fumigation process Clear procedures and documents shall be available, equipment shall be inspected to ensure readiness for use, the fumigation process shall be properly controlled, and sulphur dioxide residues shall not exceed the limits prescribed by law.

- Post-fumigation handling Sulphur dioxide gas shall be properly removed from the fumigation chamber, and residual gas on the fruits shall be released to prevent residues from exceeding the limits prescribed by law.

- Storage Treated fruits or fruits awaiting transport shall be stored in an appropriate area.

- Waste management Unused materials or wastes remaining from production shall be properly disposed of.

3. Training

- Operators have knowledge and skills appropriate for sulphur dioxide fumigation, with refresher training and updating of knowledge provided at least once a year.

4. Documents and Record Keeping

- Documents and records production process including distribution

- Keep documents and records for at least two years

Requirements for Sulphur Dioxide Fumigation of Fresh Fruits

The Agricultural Standards Act, TAS 1004-2014, is the agricultural standard concerning the code of practice for sulphur dioxide fumigation of fresh fruits. The objective of this standard is to obtain fresh fruits of good quality, safe for consumption, and without adverse impact on the environment.

Advantages of Sulphur Dioxide Fumigation of Fresh Fruits

- Build consumer confidence in the safety and quality of fresh fruits treated with sulphur dioxide fumigation.

- Operators produce and export fresh fruits that meet quality standards.

- Reduce the risks associated with sulphur dioxide contamination.

- Promotes the production of fresh fruits that are safe, environmentally friendly, and sustainable.

Academic Papers

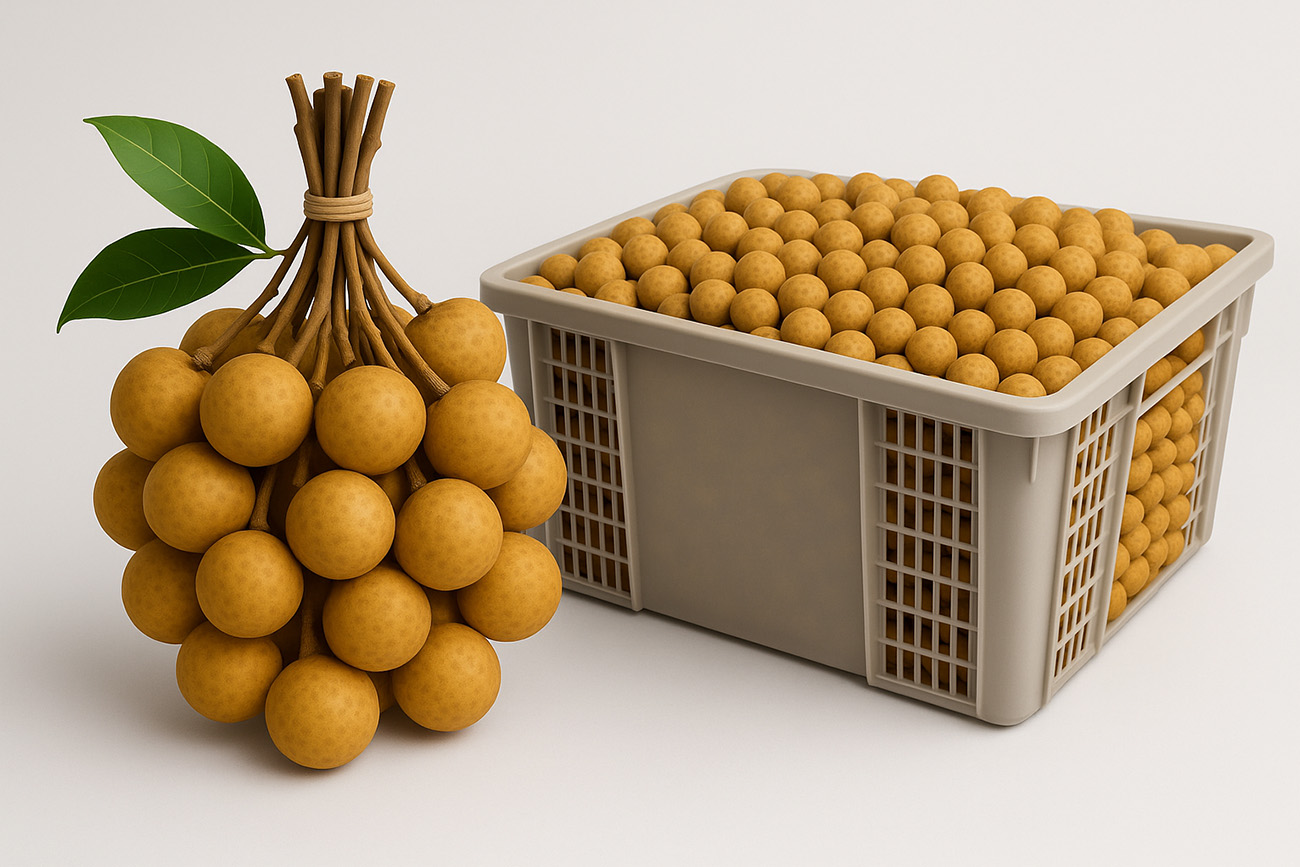

Control System for the Export of Fresh Longan to the People’s Republic of China

This document describes Thailand’s control system for exporting fresh longan to the People’s Republic of China, developed by the Department of Agriculture to comply with the Thailand–China Protocol on quarantine and food safety requirements. The system covers the registration of exporters, inspection and certification of GAP-certified orchards, approval of packing houses and sulfur dioxide fumigation facilities in accordance with TAS 1004-2014, and residue testing to ensure that sulfur dioxide in longan pulp does not exceed 50 mg/kg. Health and Phytosanitary Certificates are issued only after compliance is verified, ensuring that exported longans are safe, high-quality, and fully traceable in accordance with China’s import requirements.